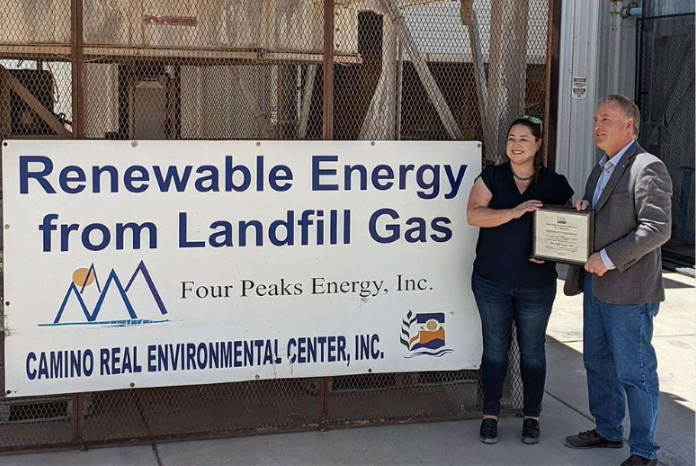

ESI president, Benny Benson, receives a Certificate of Congratulations for the successful application of federal funds for the expansion of the Four Peaks Energy Facility

Four Peaks Energy, Sunland Park, New Mexico – The USDA Rural Development State Director, Patricia Dominguez, will be awarding ESI President Benny...

.jpg)

.jpg)